Cutting Thin Metal

Introduction Fast fusion cutting of thin metal sheets a be conducted by means of CO2 lasers and solid state lasers. You probably wont find snips which are capable of cutting above 18 gauge mild steel.

What S The Easiest Way For Me To Cut Thin Metal Home Improvement Stack Exchange

What S The Easiest Way For Me To Cut Thin Metal Home Improvement Stack Exchange

The 200W laser is specified to cut the same thicknesses as the 150W laser.

Cutting thin metal. A small beam kerf allows for very intricate designs to be cut. Precision Cutting of Very Thin Metal Without Burrs Take a closer look at how extremely thin strips of anodized aluminum are slit and processed for electronics applications. Otherwise you are simply using a sledgehammer to crack nuts and losing yourself money for doing so.

Results of laser fusion cutting of thin sheet metal with a 2 kW single mode fiber and 4 kW laser will be introduced. The thinnest-possible aluminum or copper panels only around 003 mm to 03 mm thick are. Laser cutting small parts accurately and with repeatability on thinner sheet metals does require a lower power system.

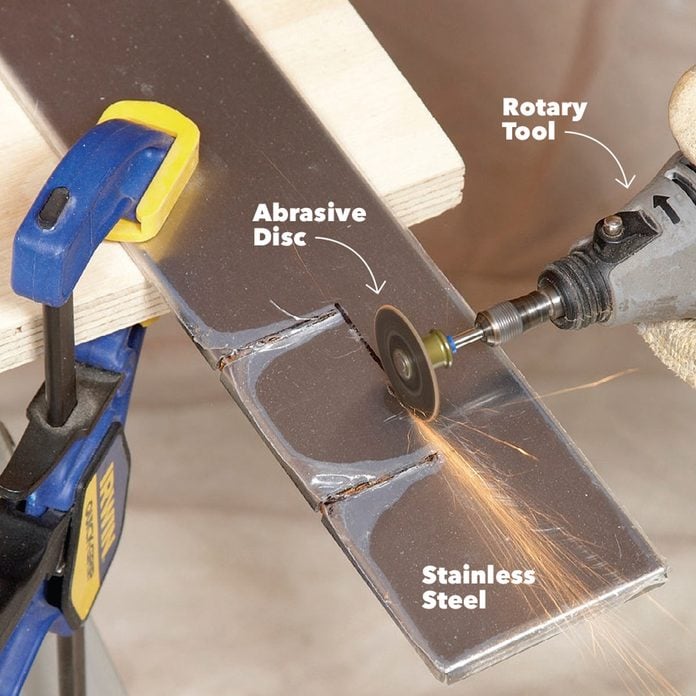

To make detailed cuts in sheet metal use a Dremel blade. Several thicknesses of electrical sheets aluminium sheets and high strength. 4Cast aluminum crossbeam Integral steel.

Galvanometer-steered thin metal cutting. FineCut consumables work with both hand-held and machine-mounted Powermax plasma torches. Here are a few tips for cutting metal with a recip saw.

However the 200W laser will cut at a higher feed rate. Using a galvanometer to steer the beam is an alternative method for laser cutting thin. FineCut consumables are ideal for cutting intricate fine-featured shapes out of thin sheet metal.

Place the metal on a hard surface to score it and on long pieces do the bending with the score place along a sharp edge of a bench and if necessary clamp the fixed piece with a long piece of flat wood to prevent buckling the metal while bending it back-and-forth. Lasers are useful for cutting thin sheet metal and foils because they make clean cuts without extra labor for refinement. These specialty consumables are specifically engineered to provide squarer edges tighter tolerances and a narrower kerf on thin metals.

Clamp the sheet metal to a work table and press the Dremel blade against it. For thin sheets of metal you can use tin snips to cut through it. Kerns metal cutting machines are capable of cutting thin gauge metal to shape.

These tools are good for cutting soft sheet metals such as tin aluminum and brass. Using a high power laser machine on thin metals can create several problems that could be avoided with a lower powered machine. A gantry or motion table moves the laser head and sheet metalachieving the full cut depth in a single pass.

A CO2 laser with 1300 W power is utilized to cut various metals with a sheet thickness of 02 mm ranging from can steel to aluminum 1. Gas-assisted thin metal cutting. A hand-operated nibbler tool like this one is a very common way to cut thin metal at home because it doesnt distort the offcut.

QCL1530 Metal and nonmetal mixed laser cutting machine 300W is a new design laser machine for cutting thin metal and non metal materials such as stainless steel alloy acrylic MDF wood etcMixed laser cutter for thin metals and thick nonmetal materials is different from the ordinary CO2 laser machine it can cut not only nonmetal materials but also thin metalsand we do not recommend to use 300w. Fiber laser cutting machine P-T for metal for carbon steel for thick sheet metal X travel. Industrial manufacturers use laser cutting for machine and electronic parts notably in the automotive and medical industries.

Aviation snips and tin snips are a common method of cutting thin sheet metal for hobbyists. On-axis gas assist further reduces the head-affected zone and oxidation on cuts while preventing slag on the back side. A hand-operated nibbler is perhaps the most common tool people use to cut thin metal at home.

Choose a blade with 20 to 24 TPI teeth per inch for thin metal 10 to 18 TPI. The two most common laser cutting methods are. Set your saw to straight rather than oscillating if theres a choice.

Like the name suggests it cuts about a 18x14 nibble at a time. Cutting Thin Slots In Metal is won the jackpot for the next play is reset to a predetermined value then resumes increasing Cutting Thin Slots In Metal with each play. Flexible and Exquisite Space structure is effectively used cutting area is 1000x1500mm saving space and resources the equipment can be moved flexibly.

Extend blade life by keeping the saws speed slow. Some games even feature a progressive jackpot network Cutting Thin Slots In Metal thats linked. Thin sheet metal used for shearing and splicing tends to be below 6 mm in thickness.

10 Easy Ways To Cut Metal Fast The Family Handyman

10 Easy Ways To Cut Metal Fast The Family Handyman

Hifocus 161i Neo Cutting 2 Mm Thin Stainless Steel Dunnblech Edelstahl Kjellberg Youtube

Hifocus 161i Neo Cutting 2 Mm Thin Stainless Steel Dunnblech Edelstahl Kjellberg Youtube

How To Cut Thin Sheet Metal And Keep It Flat Instructables

How To Cut Thin Sheet Metal And Keep It Flat Instructables

4 Ways To Cut Sheet Metal Wikihow

4 Ways To Cut Sheet Metal Wikihow

4 Ways To Cut Sheet Metal Wikihow

4 Ways To Cut Sheet Metal Wikihow

How To Cut Thin Sheet Metal And Keep It Flat Instructables

How To Cut Thin Sheet Metal And Keep It Flat Instructables

How To Cut Thin Metal At Home The Silicon Underground

10 Easy Ways To Cut Metal Fast The Family Handyman

10 Easy Ways To Cut Metal Fast The Family Handyman

Eastwood Metal Cutting Tools How To Cut Sheet Metal To Thick Plate Youtube

Eastwood Metal Cutting Tools How To Cut Sheet Metal To Thick Plate Youtube

150w Thin Metal Sheet Co2 Cnc Laser Cutting Machine For A6s Cutting Ss 1 7mm Youtube

150w Thin Metal Sheet Co2 Cnc Laser Cutting Machine For A6s Cutting Ss 1 7mm Youtube

4 Ways To Cut Sheet Metal Wikihow

4 Ways To Cut Sheet Metal Wikihow

How To Cut Thin Metal Precisely Kevin Caron Youtube

How To Cut Thin Metal Precisely Kevin Caron Youtube

4 Ways To Cut Sheet Metal Wikihow

4 Ways To Cut Sheet Metal Wikihow

Comments

Post a Comment