Sweating Copper Fittings

18 in 14 in 38 in 12 in 58 in 34 in 1 in 1-14 in 1-12 in 2 in 2-12 in 3 in 4 in 5 in 6 in 8 in. Spread soldering flux on the outside of the pipe and the inside of the brass fitting with a small brush.

How To Sweat Copper Pipes And Fittings Planitdiy

I had a plumbing problem needing to be addressed people.

Sweating copper fittings. Stop mixing copper with cast iron piping and learned how to sweat solder copper piping. Fittings have good corrosion resistance. Its called that because the process of joining the various.

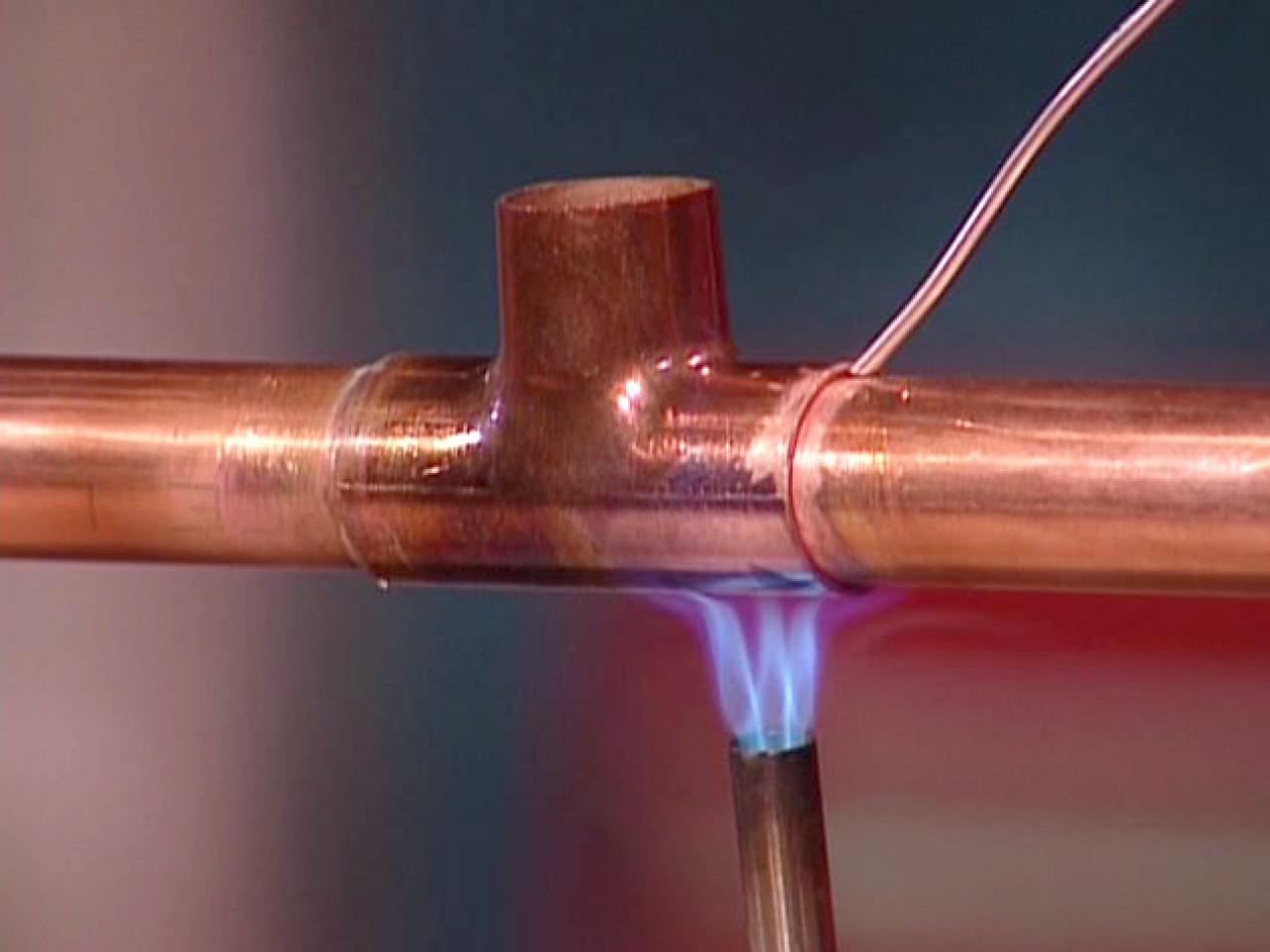

The plumber applies the solder to the juncture of the pipe and fitting making it watertight and permanent. They are also known as sweat fittings. Clamp the pipe between the cutting wheel and the guide wheel and rotate the cutter scoring the pipe all the way around.

Solder these fittings to copper tubing or the tube end of another fitting for a permanent leak-tight connection. Cut copper tubing cleanly with a tube cutter. Heat the joint with a propane torch until the flux begins to boil.

Knowing how to sweat copper pipe allows a do-it-yourselfer to install pipe yourself. They are also known as sweat fittings. Looks better but it doesnt do anything else.

Wiping a rag on the fitting isnt needed all that does is smear the solder thats hanging on the outside of the fitting around. The walls of copper pipe however are too thin and soft to be threaded so a different sort of fitting is used called a sweat fitting. In this video ill explain and show you exactly how to unsolder a copper joint to be able to reuse it in the future and save lots of -----.

A properly sweated joint will last for years in many cases decades. Heres a solder like a pro without having a messy looking jointMy web store. Sweating a copper water line is relatively easy.

Plumbers join copper pipe with a torch and soldering paste in a process called sweating pipe. Propane is plenty hot for normal sized copper piping up to 3 or so. Slip the fitting onto the pipe and rotate it into the correct orientation.

The brush usually comes with the flux. Also remember that MAPP gas burns hotter than propane. To adhere to safety standards for drinking water systems use fittings that meet NSFANSI 61 EN 1057 or DVGW GW 8 P.

Solder these fittings to copper tubing or the tube end of another fitting for a permanent leak-tight connection. How to Sweat solder Copper Pipe. Copper tube size is the accepted designation of the copper tubing industry not.

Fittings have good corrosion resistance. Tighten the cutter knob a quarter turn and rotate the cutter again scoring the pipe deeper. Because brazing involves higher temperatures than soldering using an oxygen-acetylene torch is your surest bet because this gets hotter than a MAPP gas or propane torch although for most small-to-medium jobs thinner copper piping a turbo torch should also work.

Sweating copper pipe isnt difficult but it takes practice. Heres a complete guide on how to repair a leaking joint whether it wasnt soldered correctly or it just started leaking in time this guide will assist you. Technically cleaning a pipe or fitting prior to soldering wont prevent oxidation but it can reveal if there is enough oxidation such that the item in.

Dont use too much flux. To make repairs it is sometimes necessary to take the joint. Copper 90 Degree Elbow.

Mastering a perfectly sweated copper joint takes a bit of practice. To adhere to safety standards for drinking water systems use fittings.

Everbilt 1 1 4 In Sweat X 1 1 4 In Mip Copper Pressure Adapter Fitting W 01171h The Home Depot

Everbilt 1 1 4 In Sweat X 1 1 4 In Mip Copper Pressure Adapter Fitting W 01171h The Home Depot

Supply Giant Dduf0018 5 Tee Copper Fittings With Sweat Ends 1 8 Amazon Com

Supply Giant Dduf0018 5 Tee Copper Fittings With Sweat Ends 1 8 Amazon Com

Solder Flux Avoid These Common Pitfalls When Sweating A Copper Joint 2016 06 13 Plumbing Mechanical

Solder Flux Avoid These Common Pitfalls When Sweating A Copper Joint 2016 06 13 Plumbing Mechanical

How To Sweat Copper Pipe Sweating Copper Pipe Joints

How To Sweat Copper Pipe Sweating Copper Pipe Joints

Diy Guy How To Sweat Copper Pipe Youtube

Diy Guy How To Sweat Copper Pipe Youtube

/Soldercopperpipe-GettyImages-157186637-597579fec4124400114f2c5f.jpg) Tools Needed For Soldering Copper Pipe

Tools Needed For Soldering Copper Pipe

How To Correctly Solder A Vertical Copper Pipe Complete Guide Got2learn Youtube

How To Correctly Solder A Vertical Copper Pipe Complete Guide Got2learn Youtube

Diy Dictionary What Is Sweating A Joint The Family Handyman

Diy Dictionary What Is Sweating A Joint The Family Handyman

How To Solder Copper Pipe Using A Propane Torch How Tos Diy

How To Solder Copper Pipe Using A Propane Torch How Tos Diy

How To Sweat Copper Pipe Diyer S Guide Bob Vila

How To Sweat Copper Pipe Diyer S Guide Bob Vila

The Basics Behind Copper Solder Fittings World Wide Metric Blog

The Basics Behind Copper Solder Fittings World Wide Metric Blog

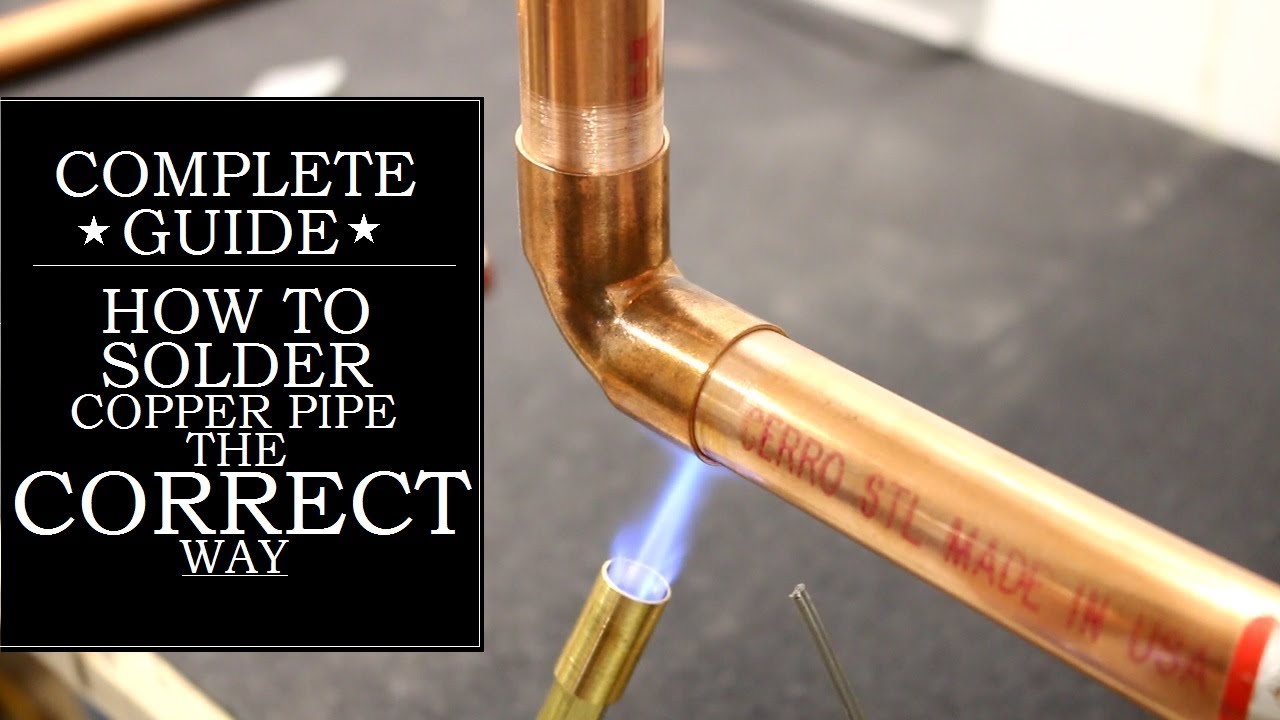

How To Solder Copper Pipe The Correct Way Got2learn Youtube

How To Solder Copper Pipe The Correct Way Got2learn Youtube

Comments

Post a Comment